[Event Report] 2022 Energy Storage Forum 儲能技術與應用論壇

Photo Gallery: Facebook

The ECCT’s Low Carbon Initiative (LCI) organised the 2022 Energy Storage Forum (儲能技術與應用論壇) together with the European Centre in Taiwan (EUTW, 臺灣歐洲聯盟中心) and TÜV Rheinland. Over 180 participants attended online.

At the event, opening remarks were made by Hsieh Han-chang, Deputy Director General of the Bureau of Standards Metrology and Inspections (BSMI), under the Ministry of Economic Affairs (MOEA, 標檢局副局長 謝翰璋); Giuseppe Izzo, ECCT Vice Chairman & LCI Chair; Dr Su Hung-dah, Director of the EUTW (臺灣歐洲聯盟中心主任 蘇宏達博士); and Jennifer Wang, Managing Director of TÜV Rheinland Taiwan (德國萊因董事總經理 王秀雲).

This was followed by presentations by representatives from government and industry experts on subjects related to energy storage, including an analysis of trends in both the international and local energy storage market, planning and policy of Taiwan’s energy storage system, the service and application of energy storage, the safety of battery management systems, an analysis of international energy storage system standards and challenges facing enterprises from carbon trading to carbon border taxes.

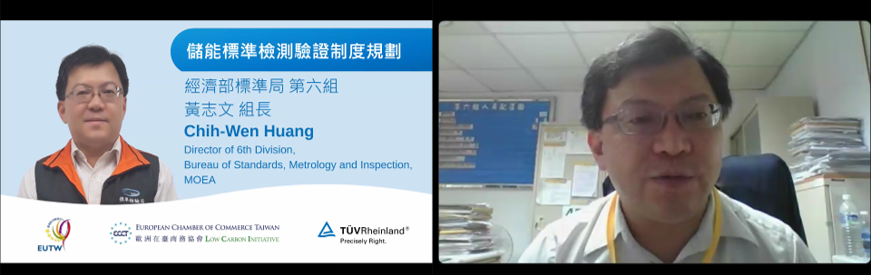

In his presentation, Huang Chi-wen, Director of the BSMI’s 6th Division (第六組組長 黃志文) gave an overview of plans for the energy storage standard testing and verification system. As part of its energy transition plans, the government has set a target of at least 1.5GW of energy storage by 2025. The plan includes formulating/revising national standards for energy storage, convening a working group comprised of representatives from industry and academia, synchronising Taiwan’s standards with international standards and establishing a verification system for energy storage products. Safety is crucial given incidences in recent years of lithium-ion batteries used for storage catching fire or exploding.

The BSMI established a working group in 2018, comprising experts and scholars. Since then, the group has held seven working group meetings to focus on the safety inspection of lithium-ion batteries. Huang went on to list the standards relevant for fixed type energy storage systems. CNS 62619 has been adopted for the testing of cells and modules in the energy storage system, and the formulation of national standards has been completed. The verification of the outdoor energy storage system project adopts the IEC 62933-5-2 international standard, and the national standard has been reconciled in advance. Two international standards related to energy storage systems have not yet been announced, and the rest will be announced in 2023 to meet the needs of industry. Testing will require energy storage system safety testing laboratories which can perform safety and combustion tests.

Energy storage projects will also need to be verified, both ahead of implementation and during operations. This will include design review (before construction) component safety in accordance with national standards (CNS), international standards (IEC) or US regulations (UL), provide, electrical/fire safety, site review (after construction is completed), on-site testing by an impartial third-party organisation and operation and maintenance requirements (periodic testing every two years) performed by an impartial third-party organisation and regular inspection of electrical equipment and regular maintenance of fire safety equipment.

In his presentation, Dr Yuan Fang-wei, Senior Analyst at Infolink (儲能資深分析師 袁芳偉博士) began with an introduction to energy storage and the role of energy storage in the grid, noting that when the irreplaceable ratio of renewable energy power generation is close to 30% of input, the scheduling and stability of the power grid should be considered. He outlined requirements for energy storage systems in different grid applications and the application and profit method of energy storage in different application scenarios.

He went on to provide an overview of the global energy storage market. The capacity of the global energy storage market was expected to exceed 10GW in 2021. China and the United States dominate the global energy storage market currently, and the gap with other regions is widening rapidly. By 2025, total energy storage demand is expected to reach more than 30GWh. Capacity in Taiwan is also expected to grow rapidly, driven by government policy. The speaker went on to give details of Taiwan’s energy storage development forecast. It is estimated that the construction volume this year will reach 100-150MW and exceed 1.5 GW / 3 GWh by 2025 and could reach 8GW / 20 GWh in 2030.

In terms of market value, by 2023, the size of Taiwan's energy storage market will exceed NT$10 billion and could reach NT$20 billion by 2025 with cumulative scale exceeding NT$200 billion by 2030. According to the speaker, although the scale of energy storage will increase rapidly from 2025 to 2030, the corresponding economic value growth rate will slow down due to the decline in energy storage prices.

Bowen Dong, Vice General Manager of Solar Commercial Products, TÜV Rheinland (德國萊因太陽能與商用工業產品服務副總經理 董斌) spoke about global energy storage applications and technical challenges. The speaker noted that by the end of 2020, the cumulative installed capacity of energy storage projects globally was 191.1GW, a year-on-year increase of 5.2%. Among them, the cumulative installed capacity of pumped storage was the largest at 172.5GW. The cumulative installed capacity of electrochemical energy storage was close behind, at 14.2GW. Among various electrochemical energy storage technologies, the cumulative installed capacity of lithium-ion batteries was the largest, at 13.1GW, exceeding the 10GW mark for the first time.

The speaker cited results from a survey conducted by TÜV Rheinland that was published in a white paper. According to survey respondents, the cost of energy storage is still too high, and in need of a clear business model for the industry. In the short term, in addition to policy support, the growth of demand is also an important factor to promote development of the energy storage industry. Price is key factor in order to realize the large-scale commercial application of energy storage, but respondents generally believe that in 2022-2023 energy storage battery prices will fall below US$0.075/kWh.

In terms of technology, lithium iron phosphate batteries are expected to be the main technical solution for energy storage in the future, and industry insiders continue to be optimistic that there will be significant technological breakthroughs in cathode material technology within three years.

Given that standards and industry norms are of great significance to product development and production and to promote industrial innovation and development, close to 80% of respondents believe that third-party testing and certification bodies should play a crucial role in promoting the sustainable and healthy development of the energy storage industry. The speaker went on to outline some of the technical challenges and security risks of energy storage systems.

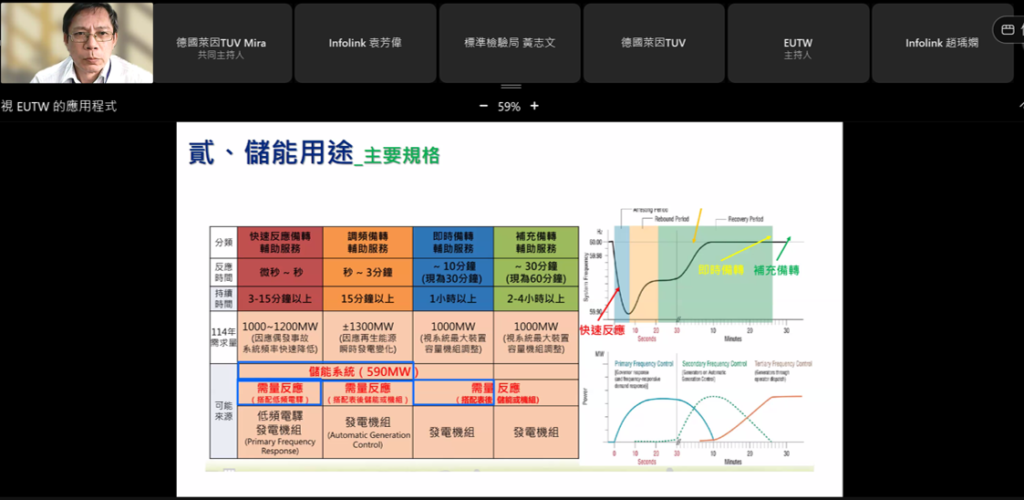

In his presentation, Chang Yao-chung, Director of Taiwan Power Company (Taipower, 台灣電力公司系統規劃處處長 張耀宗) spoke about service and application of energy storage. He noted that batteries were not the only option for energy storage. Hydro-powered pumped energy storage is also an option for Taiwan. He went on to outline the main specifications for energy storage and use cases for energy storage and safety regulations. He said that Taipower plans to build 160MW of battery energy storage at its own site and purchase 840MW of energy storage auxiliary services. He concluded that free competition will apply in the auxiliary service market and the bidding method will be adjusted periodically.

Frank Tang, Director, Department of Planning from CPC Corporation (台灣中油股份有限公司) shared experience of CPC’s smart green energy gas station in Tainan. The concept of a smart gas station is to provide charging facilities for scooters and passenger cars powered by energy from PV panels and fuel cells on site as well as back-up power from the grid. Tainan’s Qianfeng Road Station is the first carbon neutral gas station in Taiwan. Power is provided by solar panels and fuel cells and the facility includes a cloud monitoring and maintenance system. The station has a dual energy storage system and provides charging services 24 hours a day.

While not mentioned in the presentation, CPC’s Fulin Station (台灣中油福林站) in Taipei’s Shilin District is CPC’s first station to offer a range of charging for various EVs, including passenger cars and Gogoro scooters as well as EV rental services. Fulin Station’s intelligent parking space management platform, USPACE, Tesla superchargers, Gogoro Network battery swapping station, as well as car sharing services, iRent and Zipcar, and EV sharing services, Udrive and CPC Cup&Go. According to CPC, at least 22 stations with EV charging facilities will be completed by the end of 2022. The firm has also signed partnership agreements with Carrefour, City Parking and convenience store chains and aims to build 80 stations between 2022 and 2024.

Oscar Ku, Product Manager of Solar Commercial Products at TÜV Rheinland (德國萊因太陽能與商用工業產品服務專案經理 辜英洲) gave a presentation on functional safety for battery management systems. He began with definitions of safety for harm, hazards and risks as defined by ISO and IEC standards and went on to outline the risk assessment process, noting that the goal is to reduce risk to an acceptable level. IEC 60730-1 Annex H sets out the requirements for electronic controls and covers software, hardware, electromagnetic compatibility and endurance requirements. The speaker proceeded to give details about the various requirements.

Stone Wang, Senior Project Manager from TÜV Rheinland (德國萊因太陽能與商用工業產品服務資深專案經理 王磊) introduced Energy Storage System (ESS) standards. This included the types of hazards to be considered, what is covered in risk analysis and assessments in order to achieve risk reduction, noting that the priority of risk reduction approaches shall be a) inherently safe design; b) guard and protective devices; and c) provide information for end users and that it should cover the entire life cycle from R&D to repurposing or decommissioning.

Judy Chao, Researcher at Infolink (產業研究員 趙瑀嫻) gave a presentation on carbon market developments and challenges for enterprises, including carbon footprint calculations and carbon trading. She began with an overview of carbon trading and the Carbon Border Adjustment Mechanism (CBAM). The steel industry is generally the industry with the highest carbon emission among the manufacturing industries in various countries. The initially regulated industries of the carbon border adjustment mechanism are steel, cement, aluminium, imported electricity and chemical fertilizers. According to the World Steel Association, the carbon emission per tonne of steel in 2020 is 1.89 metric tonnes of carbon dioxide. She went on to describe the five steps in measuring a carbon footprint.